Roof Sandwich Panel

This Kabir Panel product has been redesigned based on research and investigation into the technical issues that occurred in the productions of some previous companies in Iran. Taking into account higher compressive and flexural strength, as well as better waterproofing and sealing, it is produced.

Kabir Panel roof panels are produced in five steps, which enhances both beauty and strength.

What is a Roof Sandwich Panel?

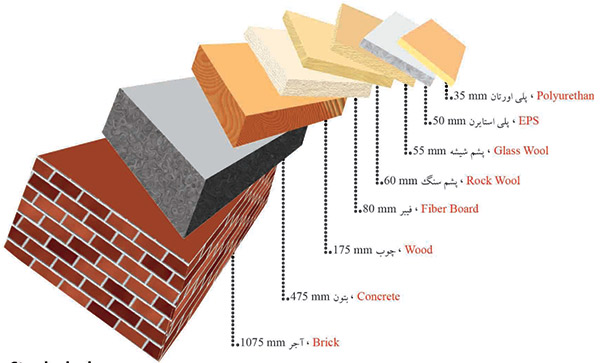

A type of building material consisting of two layers of sheets with foam injected between them, used to cover the roof, is called a roof sandwich panel, with the best type of foam used being polyurethane foam, both in terms of insulation and strength in roof sandwich panels.

Advantages of Roof Sandwich Panels:

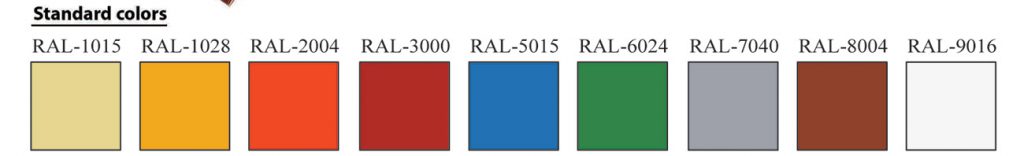

Thermal and cold insulation, sound insulation, moisture resistance, lightweight construction leading to reduced weight of the structure, speed in implementation, and reduction of project duration costs, earthquake resistance, increased lifespan of buildings and facilities, and aesthetic design and color variety.

Applications of Roof Sandwich Panels:

Roof sandwich panels are used to cover roofs of industrial halls, sports halls, prefabricated cabins, villa buildings, aircraft hangars, and all industrial and prefabricated buildings.

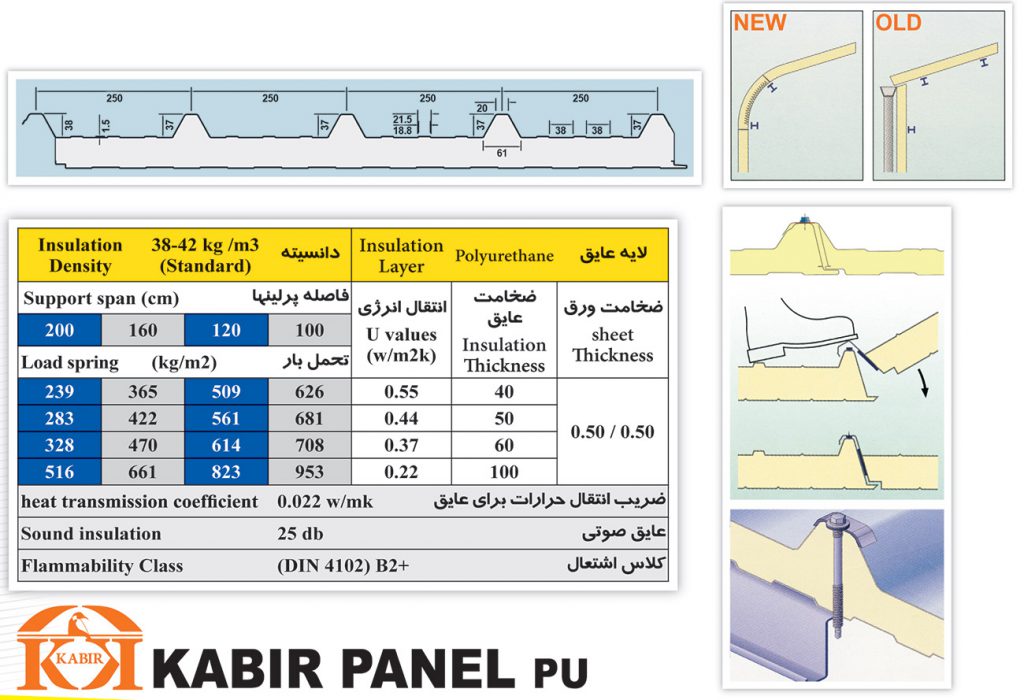

Technical Specifications of Roof Sandwich Panels:

The useful width is one meter, with a non-useful width of 1.08 meters and a length of up to 14 meters. The thickness ranges from 4 centimeters to 10 centimeters, and the sheets used are galvanized and aluminum types, produced in double-sided or single-sided foil forms.

Roof sandwich panels are available in two types: regular and fire-resistant. Roof sandwich panels can be produced in double-sided sheet, single-sided sheet with nylon, single-sided sheet with foil, or single-sided sheet with paper forms.

Advantages of Using Roof Sandwich Panels:

The advantages of using roof sandwich panels are numerous, some of which include: roof sandwich panels are a type of building material consisting of two sheets with foam injected between them.

The material of these sheets is aluminum, galvanized, and Aluzinc. Aluminum sheets are corrosion-resistant and suitable for moist environments. Aluzinc sheets, in addition to being corrosion-resistant, have high resistance and very low corrosion, and their price is very low and suitable. The best type of foam used in roof sandwich panels is polyurethane foam.

Installation of Roof Sandwich Panels:

First, attention should be paid to the structure implemented on the roof and the distance between the main supports, and then the roofing of the roof panels should be done according to the substructure.

In the next step, the sandwich panels are placed on the existing purlins on the roof, and one galvanized self-drilling screw should be used for each square meter of roof sandwich panel.

The sandwich panels must be laid in an overlapping manner. This is done for roof waterproofing and preventing water penetration, which is very important.

Finally, for beautification and sealing of the building, it is advisable to use flashing sheets and eave sheets.